-

ADD:

5F, No.657-3, Zhongzheng Road, Xinzhuang District, New Taipei City 242, Taiwan -

TEL:

+ 886-2-2209-1343 -

FAX:

+ 886-2-2903-0754 -

E-mail:

sales@greenconn.com

-

ADD:

No. 22 Jingshan Road, Luotian Third Industrial Zone, Yanluo Street, Baoan District, Shenzhen City, Guangdong Province, China -

TEL:

+ 86-755-2707-0050/1 -

FAX:

+ 86-755-2707-0056 -

E-mail:

sales@greenconn.com

-

ADD:

2003, 24 Wellesley Street West, Toronto, Ontario, M4Y 2X6 -

TEL:

+ 1-704-493-1478 -

E-mail:

sales@greenconn.com

Automotive Connectors

Automotive electrical connectors are used in electrical systems within automobiles. These electrical connectors have changed dramatically in today's modern world, and Greenconn offers the solutions to accommodate for these innovative advancements. As automotive systems become more and more complex, the demand for these electrical connectors continues to grow. Greenconn has the capability of producing all your connector needs while offering short lead times and cost-effective solutions.

Types of Automotive Connectors

Automotive Electrical Connectors

Greenconn's automotive electrical connectors offer high levels of precision and mechanical strength, and can be applied to various applications susceptible to harsh environmental conditions. Our automotive electrical connectors are waterproof, dustproof, and resistant against high strength vibration and impact, high temperature, and corrosion. Greenconn's connectors supply stable electrical performance (high current flow with low impedance) and strong interconnection with options applicable to board-to-board, board-to-wire, and wire-to-wire connectors. Our connectors can also be customized according to the needs of our customers.

Press-Fit

For Greenconn's Press Fit connectors, a crimp connection process is used to connect the connector to the circuit board. This specific connector provides numerous advantages during assembly. In comparison to other connectors, these connectors do not require soldering, so less materials are used during assembly, and the PCB does not need to be cleaned after the flux process saving time and costs. Our press-fit connectors leave no leftover reflux residue which creates for a more environmentally friendly product. In addition, because these connectors are directly inserted into the PCB and locked into place, soldering mistakes become obsolete. Greenconn's press fit connectors are easy to remove, replace and provide high electrical reliability.

Why Choose Greenconn for your Automotive Connector Needs?

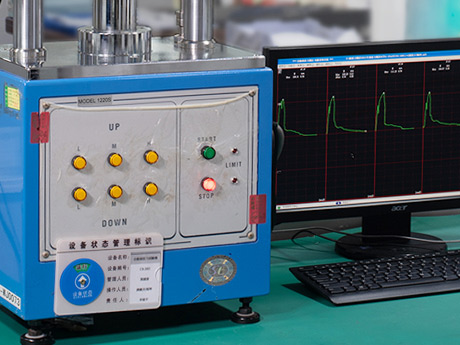

Greenconn is a professional electrical connector manufacturer certified with IATF16949 qualification for the automitive industry. Along with this, Greenconn has 23 years of experience providing robust solutions to our customers all across the globe. We provide innovative, durable solutions and clear, prompt service offered at competitive prices. Our products are reliable and made to last.

How to Protect Automotive Electrical Connectors?

While the wires and pins within connectors are responsible for providing a consitant electrical current to be made, protecting those wires and connectors is just as important. Greenconn's wire insulation and connector housings allow our connectors to be used in extreme conditions over an extended period of time. We provide connectors that are resistant to water, dust, vibration, shock, corrosion, etc. This allows our products to be used in all kinds of applications within the automotive industry.

What to Consider when Choosing a Greenconn Automotive Electrical Connector?

- Mechanical Performance: mechanical life, mechanical foolproof, connector plugging force, etc.

- Electrical Performance: limiting current, contact resistance, insulation resistance and dielectric strength.

- Environmental Performance: temperature resistance, humidity resistance, salt spray resistance, vibration, shock, etc. (Make sure to choose a connector according to the specific environmental conditions of the application. If, for example, the application's environmental conditions are relatively humid, the requirements for a connector's resistance to humidity and corrosion should be high in order to prevent the connector's metal contacts from becoming corroded. These conditions will also need to be considered in accordance to ISO16750).