Features and Advantages of Automotive PCB Header Connectors with Plastic Frames

With the rapid development of telecommunication, automotive, and industrial fields, traditional connectors with single function and unstable performance can no longer meet industry requirements. To improve on the traditional connectors, headers with plastic frames have made functional integration and design optimization to match a variety of application requirements. Therefore, these PCB headers with a special plastic frame have been widely used in automotive applications requiring new features and functions. In the following paragraphs, we will briefly summarize the main features and advantages of automotive PCB header connectors with plastic frames to help customers better design their application solutions.

1.Multifunctional integrated design

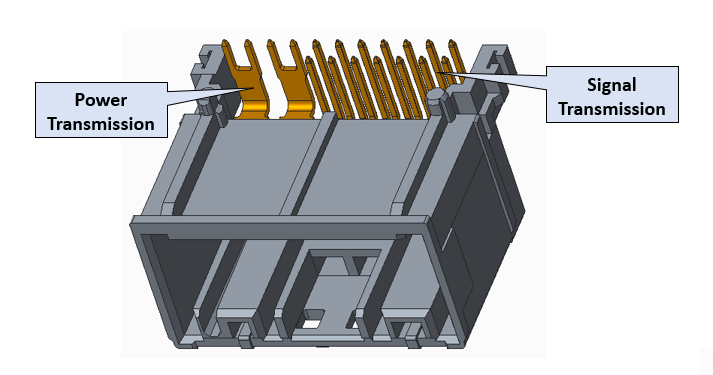

Automotive PCB header connectors with plastic frames integrate multiple functions, which can realize the transmission of power and signal simultaneously, greatly expanding the use of the product to meet the diverse needs of users. The multi-functional integration capability can better maximize the efficiency of the electronic connector and save assembly space and costs.

Automotive PCB header connectors with plastic frames integrate multiple functions, which can realize the transmission of power and signal simultaneously, greatly expanding the use of the product to meet the diverse needs of users. The multi-functional integration capability can better maximize the efficiency of the electronic connector and save assembly space and costs.

Figure 1: Header connectors with plastic frames combine the transmission of power and signal

Figure 1: Header connectors with plastic frames combine the transmission of power and signal2. Plastic housing guide connection and mating of high stability

Automotive PCB header connectors with plastic frames are extremely stable. First of all, the plastic frame of the connector can wrap the body and better protect the connector from damage due to skewed mating during the plugging process. At the same time, the locking design also allows for the connection to be reinforced from the inside of the connector so as to avoid shedding during use ensuring the stable transmission of power and signal, as well as a safe use of the product.

Automotive PCB header connectors with plastic frames are extremely stable. First of all, the plastic frame of the connector can wrap the body and better protect the connector from damage due to skewed mating during the plugging process. At the same time, the locking design also allows for the connection to be reinforced from the inside of the connector so as to avoid shedding during use ensuring the stable transmission of power and signal, as well as a safe use of the product.

Figure 2:The plastic housing guide and locking mechanism features of automotive PCB header connectors

Figure 2:The plastic housing guide and locking mechanism features of automotive PCB header connectors3. High efficiency and resistance of external interference

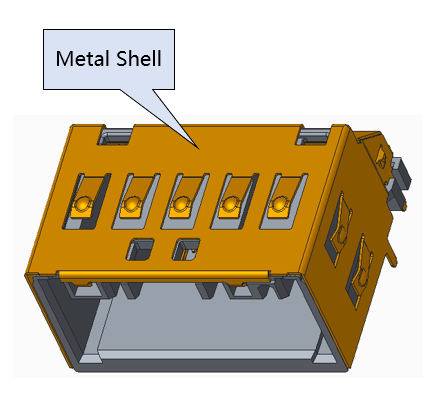

A metal shell can be added to the outside of the header connector to effectively shield the interference of various external electronic signals and further ensure a stable transmission process. This function is particularly important in the use of automotive connectors. Meanwhile, the metal shell can also play a vital role in protecting the internal materials from being damaged due to external pressure, which greatly improves the quality and service life of the electronic connector.

A metal shell can be added to the outside of the header connector to effectively shield the interference of various external electronic signals and further ensure a stable transmission process. This function is particularly important in the use of automotive connectors. Meanwhile, the metal shell can also play a vital role in protecting the internal materials from being damaged due to external pressure, which greatly improves the quality and service life of the electronic connector.

Figure 3: Metal shell wrapped around the outside of the header connector

Figure 3: Metal shell wrapped around the outside of the header connectorAs a leading manufacturer committed to the R&D and production of innovative connectors for 25 years, Greenconn has exported various types of PCB header connectors with plastic frames into the global market, with increasing sales volume from year to year. Connectors used in automotive applications are mostly customized products due to the high requirements on safety, stability, and functionality. But with continuous technological breakthroughs, fast market response, and high-quality customized services, Greenconn has successfully introduced various types of customized automotive PCB header connectors based on vehicle-specific needs to the supply chains of BMW, Ford, Mercedes-Benz, BYD and other well-known car manufacturers with continuous and stable supply. For more details, contact us now!