The Connection Forms of Industrial Connectors

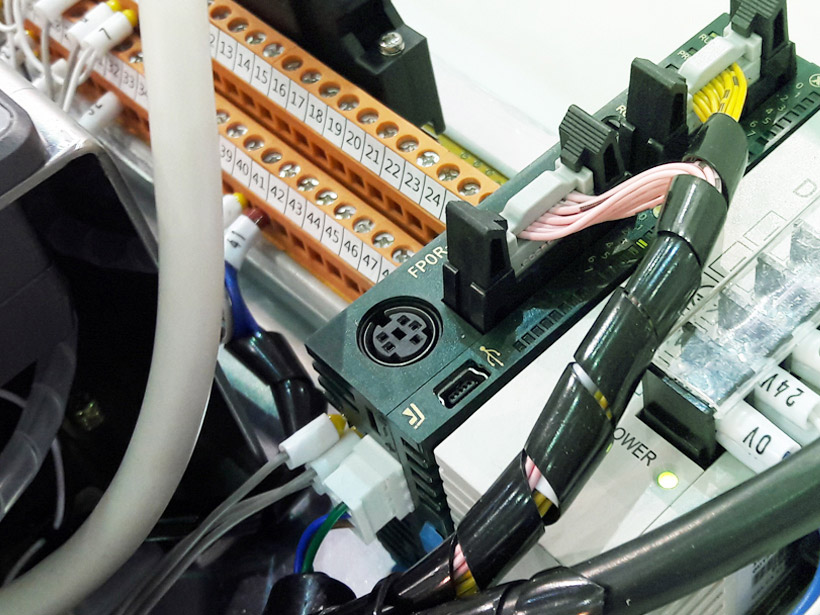

Industrial connectors are mainly used for electrical signal transmitting and controlling as well as power connections between electronic and electrical equipment. They are electrical connectors designed specifically to establish strong Ethernet connections in harsh environments, with the advantages of being more robust and resistant.

The connection form is an important factor affecting the performance and user experience of the connector in a specific environment; therefore, it has become one of the key considerations for users when choosing industrial connectors. Here are four common connection forms of industrial connectors:

1.External thread connection

External thread connection has good stability, simple processing technology, and lower manufacturing costs, making it a frequently chosen connection form for large-scale touch and obvious vibration working environments. A fuse that will not loosen after installation can be installed with this connection form. This connection form is reliable but has a slow connection speed and is not suitable for blind mating, frequent insertion and removal, and quick connection occasions.

2. Bayonet connection

Bayonet connection is a connection form that can achieve fast connection and separation. Most electrical industrial connectors with locking connection forms have an image of the appropriate connection and the lock, which can be observed in the small circular hole on the side of the electrical connector connecting nut.

3.Plug-in connection

The plug-in connection is a multifunctional connection form. When the power plug and socket of the industrial connector are connected and disconnected, the movement direction is usually a repeated constant-speed linear motion without the need for rotating motion, and only a small workspace is required to complete the connection and separation. This connection form is suitable for fast insertion and removal and for connections with small usage spaces.

Typical plug-in connections have two structures: ball or pin. This connection form does not have a labor-saving structure mechanically, so once inserted incorrectly, the friction resistance of the mechanical equipment will increase and can be immediately discovered.

4. Server cabinet connection

This connection mode is used for industrial connectors on mechanical equipment that need to be blindly connected near the frame, making electrical equipment light and small, and easy to maintain. This connection form of industrial connectors does not give a sense of the connection status, so it requires an accurate positioning design to avoid misinsertion. Cabinet-style electrical connectors usually use floating or elastic contact design structures to ensure proper connection.

Industrial connectors have provided equipment with connection services for many years, but with the continuous deterioration of application scenarios, the characteristics and reliability of early industrial connectors have decreased, prompting innovation and upgrades of the new next-generation industrial connectors.

Greenconn has accumulated years of experience in the manufacturing of industrial connectors since its establishment in 1998, and its products have been widely used in well-known industrial factories such as Schneider, Omron, and Nidec. If you have any needs, please feel free to contact us.

The connection form is an important factor affecting the performance and user experience of the connector in a specific environment; therefore, it has become one of the key considerations for users when choosing industrial connectors. Here are four common connection forms of industrial connectors:

1.External thread connection

External thread connection has good stability, simple processing technology, and lower manufacturing costs, making it a frequently chosen connection form for large-scale touch and obvious vibration working environments. A fuse that will not loosen after installation can be installed with this connection form. This connection form is reliable but has a slow connection speed and is not suitable for blind mating, frequent insertion and removal, and quick connection occasions.

2. Bayonet connection

Bayonet connection is a connection form that can achieve fast connection and separation. Most electrical industrial connectors with locking connection forms have an image of the appropriate connection and the lock, which can be observed in the small circular hole on the side of the electrical connector connecting nut.

3.Plug-in connection

The plug-in connection is a multifunctional connection form. When the power plug and socket of the industrial connector are connected and disconnected, the movement direction is usually a repeated constant-speed linear motion without the need for rotating motion, and only a small workspace is required to complete the connection and separation. This connection form is suitable for fast insertion and removal and for connections with small usage spaces.

Typical plug-in connections have two structures: ball or pin. This connection form does not have a labor-saving structure mechanically, so once inserted incorrectly, the friction resistance of the mechanical equipment will increase and can be immediately discovered.

4. Server cabinet connection

This connection mode is used for industrial connectors on mechanical equipment that need to be blindly connected near the frame, making electrical equipment light and small, and easy to maintain. This connection form of industrial connectors does not give a sense of the connection status, so it requires an accurate positioning design to avoid misinsertion. Cabinet-style electrical connectors usually use floating or elastic contact design structures to ensure proper connection.

Industrial connectors have provided equipment with connection services for many years, but with the continuous deterioration of application scenarios, the characteristics and reliability of early industrial connectors have decreased, prompting innovation and upgrades of the new next-generation industrial connectors.

Greenconn has accumulated years of experience in the manufacturing of industrial connectors since its establishment in 1998, and its products have been widely used in well-known industrial factories such as Schneider, Omron, and Nidec. If you have any needs, please feel free to contact us.