Key metrics for choosing materials in floating connectors

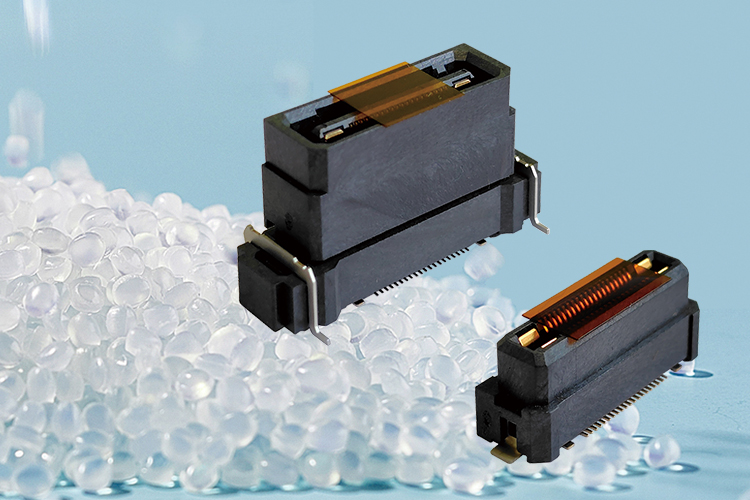

In the design and manufacturing of floating connectors, material selection is a crucial step that directly impacts the reliability, durability, and overall performance of the connectors in complex and variable application environments. Drawing from its expertise in connector manufacturing, Greenconn has compiled a comprehensive list of key performance indicators to take into account when choosing materials for floating connectors.

By taking into account the indicators mentioned above, manufacturers can carefully choose the right materials for floating connectors in different application scenarios, ensuring exceptional performance and long lifespan.

As a leading connector manufacturer, Greenconn is committed to providing customizable, high-performance floating connector solutions for its customers. We keep pace with the times, continuously exploring new materials and processes to meet the increasingly stringent requirements for connectors in cutting-edge fields such as high-speed communication, new energy vehicles, and industrial automation. Through strict quality control and continuous technological optimization, we ensure that every product can maintain excellent performance and reliability in various extreme environments. At the same time, we actively respond to environmental calls, promoting green production and contributing to sustainable development.

- Conductivity: Excellent conductivity is the foundation for ensuring efficient and lossless current transmission, which is critical for maintaining the stable operation of electronic devices.

- Elasticity: The spring mechanism in floating connectors requires materials with good elasticity to effectively absorb and mitigate vibrations and shocks, protecting electrical connections from external factors.

- Wear Resistance: Choosing highly wear-resistant materials ensures that the connector maintains stable electrical contact and precision over long-term use, extending the product's lifespan.

- Temperature Resistance: With the increasing operating temperatures of modern electronic devices, the temperature resistance of materials has become an important indicator for assessing their suitability. Connector materials must maintain stable performance over a wide temperature range, including extreme high temperatures.

- Corrosion Resistance: For connectors operating in humid environments or those exposed to corrosive gases or liquids, corrosion resistance is crucial. It effectively prevents performance degradation or failure due to chemical corrosion.

- Mechanical Strength: Sufficient mechanical strength ensures that the connector can withstand various mechanical stresses, such as insertion force and bending stress, during assembly and use, maintaining structural integrity and stability.

- Coefficient of Thermal Expansion: Selecting materials with a coefficient of thermal expansion that matches that of the PCB helps reduce thermal stress caused by temperature changes, protecting the circuit connections from damage.

- Flame Retardancy: In applications requiring compliance with safety standards, using flame-retardant materials can effectively reduce fire risk and enhance overall product safety.

- Density and Weight: With the rise of lightweight design, the density and weight of materials have become important considerations in certain application fields. Choosing low-density, lightweight materials helps reduce the total weight of the system, improving overall performance and efficiency.

- Cost-Effectiveness: Manufacturers must balance performance, quality, and cost-effectiveness when making decisions. By making sensible choices in material selection, products can gain a competitive edge in the market and accommodate a wide range of budget preferences.

By taking into account the indicators mentioned above, manufacturers can carefully choose the right materials for floating connectors in different application scenarios, ensuring exceptional performance and long lifespan.

As a leading connector manufacturer, Greenconn is committed to providing customizable, high-performance floating connector solutions for its customers. We keep pace with the times, continuously exploring new materials and processes to meet the increasingly stringent requirements for connectors in cutting-edge fields such as high-speed communication, new energy vehicles, and industrial automation. Through strict quality control and continuous technological optimization, we ensure that every product can maintain excellent performance and reliability in various extreme environments. At the same time, we actively respond to environmental calls, promoting green production and contributing to sustainable development.