Greenconn's Industrial Connectors Boost the Upgrading of Industrial Robots and Industrial Automation

At present, China's industrial robot market accounts for about one-third of the global market share and holds the world's largest industrial robot application market. Being one of the key components, the connector provides signal, power, and current to the robotic application. By now, along with the continuous development of industrial automation, the demand for industrial robotics continues to grow, which brings more opportunities and challenges to the industrial connector field. New products need to be continuously innovated and upgraded to adapt to these more intelligent applications.

As a senior enterprise with more than 24 years of experience in connector R&D and manufacturing, Greenconn is well aware of the importance of connectivity technology in realizing the intelligent manufacturing upgrading of industrial robots and boosting the development of industrial automation in the direction of modularization, miniaturization and interconnection. To achieve the high-precision, high-speed, high-integration performance of industrial connectors, and combine module assembly, convenient plugging, cost optimization and other advantages as a whole, Greenconn has increased investment and made a comprehensive layout in all sessions of connector technology R&D, technology upgrading, production, and manufacturing.

1. High Precision

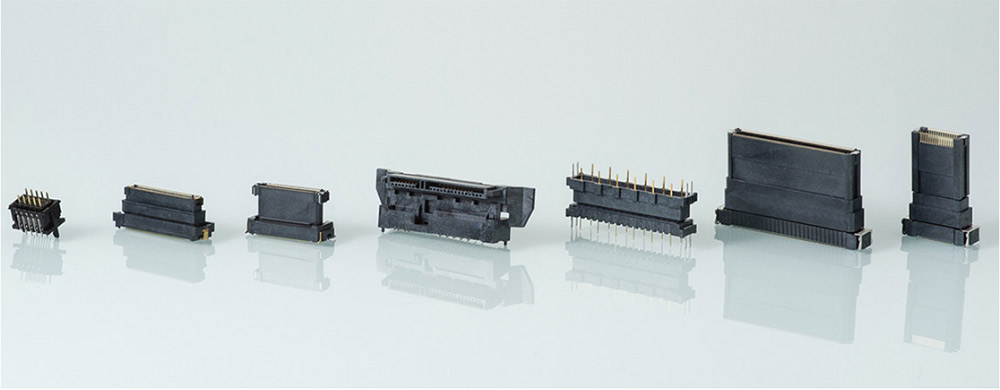

Due to production needs, industrial robotics are generally used in a working environment with high vibration, high speed and high temperature, and also tend to be more and more miniaturized. Therefore, industrial connectors also need to meet the needs of miniaturization and refinement while continuing to maintain high stability. Relying on many years of connector manufacturing experience, Greenconn has carried out innovative adaptations in the development and production of a new generation of industrial connectors, from solution design to production process. The transmission function of both power and signal, along with other mechanical features such as vibration resistance, anti-interference performance, insertion and withdrawal durability are integrated in a smaller design, just like its newly launched floating connector series.2. High Speed

The widespread application of 5G technology requires industrial connectors to undertake more secure, stable and high-speed signal transmission tasks. Greenconn takes high speed as one of the technological breakthroughs in the new generation of industrial connectors. Therefore, in addition to being small and precise, it also has large-capacity data transmission capabilities and faster signal transmission speed, meeting the needs of intelligent industrial robots for the high-speed transmission of diversified data.3. High Integration

With the miniaturization of electronic equipment and control systems such as industrial robots, the corresponding connector products need to achieve narrower pitch and higher integration while maintaining high stability. For example, as the number of pins in a single connector increases, the signal transmission channels become more abundant and multifunctional. By implementing solutions like this, Greenconn continuously improves its precision machining capabilities, and implements refined operations in molding, welding, and other processes to make narrower spacing and high reliability, thereby achieving a higher level of integration.Today, smart manufacturing and industrial automation are advancing at an alarming rate, with ever-changing demands for key components such as connectors, and higher requirements for product specifications. Greenconn keeps up with the pace of the market, drives R&D through innovation, and continuously conducts technological iterations to provide more compact and intelligent industrial connector products for industrial robots and other application fields, so as to meet the constantly evolving and stringent demands in the development of industrial automation.