How Much Do You Know About Floating Connectors

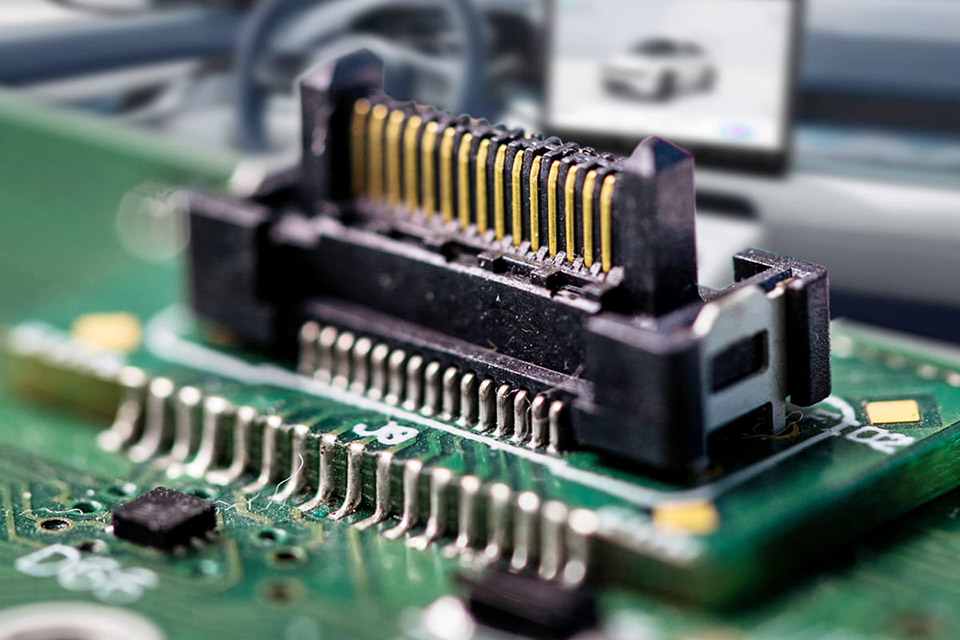

Floating connectors, also known as floating pins or floating terminals, are electrical components used to establish temporary or intermittent connections between electronic devices or circuits. They are typically found in connectors or sockets and provide a means of connecting and disconnecting circuits without a permanent physical connection.

The term "floating" refers to the ability of the connector pins or terminals to move or float within the connector housing. This movement allows the pins to make contact with corresponding terminals in another connector, creating an electrical connection. When the connectors are disconnected, the pins return to their original position within the housing.

Floating connectors are commonly used in situations where there is a need for flexibility or ease of connection. They are often employed in applications such as test and measurement equipment, modular systems, and interconnect solutions where frequent connection and disconnection are required. By using floating connectors, the risk of damage to the pins or terminals due to repeated insertion and removal is minimized.

One example of floating connectors is the card edge connectors used in computer systems. These connectors have a row of pins that align with a corresponding set of terminals on an expansion card. The pins are designed to float within the connector, allowing for easy insertion and removal of the card.

Another example is the floating connectors used in audio and video equipment. These connectors, such as RCA or HDMI connectors, have pins that can move within the connector housing, ensuring proper alignment and contact when connecting devices.

Floating connectors can also be found in automotive applications, aerospace systems, and various industrial settings. They provide a reliable and convenient means of connecting and disconnecting circuits without the need for permanent soldered connections.

In automotive applications, floating connectors are commonly used for connecting various electrical components, such as sensors, actuators, modules, and wiring harnesses. They allow for easy installation, maintenance, and repair of electrical systems within vehicles. By using floating connectors, automotive manufacturers can avoid the need for permanent soldered connections, which makes it more convenient to replace or upgrade components when necessary.

Similarly, in aerospace systems, floating connectors play a crucial role in connecting and disconnecting electrical circuits. They are used in avionics systems, satellite communication systems, and other aircraft electronics. The floating connectors enable easy access to electrical connections during installation, maintenance, and repair activities. The ability to disconnect and reconnect circuits without soldering is particularly advantageous in aerospace applications, where components may need to be replaced or serviced in remote or challenging environments.

In various industrial settings, floating connectors are utilized for connecting equipment, machinery, and control systems. They provide a reliable and efficient means of establishing electrical connections, allowing for modular configurations and easy reconfiguration of systems. Industries such as manufacturing, automation, robotics, and energy rely on floating connectors to facilitate flexible and interchangeable electrical connections without the need for permanent soldering.

The term "floating" refers to the ability of the connector pins or terminals to move or float within the connector housing. This movement allows the pins to make contact with corresponding terminals in another connector, creating an electrical connection. When the connectors are disconnected, the pins return to their original position within the housing.

Floating connectors are commonly used in situations where there is a need for flexibility or ease of connection. They are often employed in applications such as test and measurement equipment, modular systems, and interconnect solutions where frequent connection and disconnection are required. By using floating connectors, the risk of damage to the pins or terminals due to repeated insertion and removal is minimized.

One example of floating connectors is the card edge connectors used in computer systems. These connectors have a row of pins that align with a corresponding set of terminals on an expansion card. The pins are designed to float within the connector, allowing for easy insertion and removal of the card.

Another example is the floating connectors used in audio and video equipment. These connectors, such as RCA or HDMI connectors, have pins that can move within the connector housing, ensuring proper alignment and contact when connecting devices.

Floating connectors can also be found in automotive applications, aerospace systems, and various industrial settings. They provide a reliable and convenient means of connecting and disconnecting circuits without the need for permanent soldered connections.

In automotive applications, floating connectors are commonly used for connecting various electrical components, such as sensors, actuators, modules, and wiring harnesses. They allow for easy installation, maintenance, and repair of electrical systems within vehicles. By using floating connectors, automotive manufacturers can avoid the need for permanent soldered connections, which makes it more convenient to replace or upgrade components when necessary.

Similarly, in aerospace systems, floating connectors play a crucial role in connecting and disconnecting electrical circuits. They are used in avionics systems, satellite communication systems, and other aircraft electronics. The floating connectors enable easy access to electrical connections during installation, maintenance, and repair activities. The ability to disconnect and reconnect circuits without soldering is particularly advantageous in aerospace applications, where components may need to be replaced or serviced in remote or challenging environments.

In various industrial settings, floating connectors are utilized for connecting equipment, machinery, and control systems. They provide a reliable and efficient means of establishing electrical connections, allowing for modular configurations and easy reconfiguration of systems. Industries such as manufacturing, automation, robotics, and energy rely on floating connectors to facilitate flexible and interchangeable electrical connections without the need for permanent soldering.